The NEW KD Catalogue – Behind the Scenes!

Share

Welcome readers to this week’s blog post where we’ll be sharing the inside scoop about the ‘making of’ project for our brand-new product catalogue. Launched last week, this is our first ever product catalogue that’s now available to download and peruse at your pleasure. We’ll be sharing the behind the scenes processes and techniques we implemented to get the perfect shots on our custom-built photography set that we built especially for Kimber Doll.

In the heart of our Australian warehouse is our 6m x 3m purpose-built photography set that’s large enough for a full bedroom ensemble. We constructed this back in 2017 and have since had fantastic use from it for both photography and videography projects for Kimber Doll.

Construction was a week-long build that was both enjoyable for our team and also a bonding experience for all. The size and usability were very important for us, with the anticipation of projections such as this catalogue and unique photography requirements.

In particular, our techniques to capture to most clean and precise ‘standing’ position involved a gantry system. See below the lengths we went to, which required using some spare pallet racking from our warehouse that was tall enough and sturdy enough to suspend Kimber Doll in all her glory.

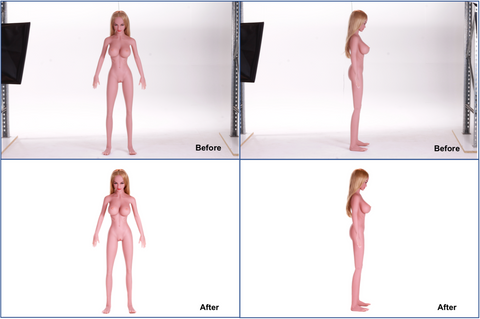

After the photography process, (48 hours) we then do our own in-house editing using professional software. This stage can also take several days to get all images looking as pristine as possible. The before and after comparisons show just how much effort is required, even with pro-level lighting and optimised camera settings.

Suspending Kimber was done carefully using a modified M16 threaded section between her body and head. This threaded section was originally a longer bolt that we machined down to allow for safe connection and accommodation for the 4mm rope. At first, we were expecting Kimber’s head would be damaged after the completion of the project. However, we were pleasantly surprised by how resilient our flesh material stood up against the torture of a 4mm rope cutting into the back of her head. Below is an image of the same head used for this project after being suspended for 48 hours in total. Only a very small amount of stretching can be seen at the back her Kimber’s head. You can also see the rope disappearing up and around the M16 neck section.

Editing and formatting then take several more days and finally we have a completed catalogue ready to be presented within our online store.

And that’s how it’s done! We highly recommend that you download a copy of our catalogue to view Kimber Doll in an optimised format for the ultimate reading experience.

We hope you have enjoyed this inside look into our operations and the behind the scenes details of the efforts we’re constantly striving for. Our ongoing objectives are to offer our quality, affordable and long-lasting products with A1 customer service to our customers.

Please don’t hesitate to get in touch with one of our friendly customer service staff members and we’ll get back to you within one business day.

Thank you for reading.

- Kimber Doll Team

1 comment

After a painstakingly investigation into the sex doll industry trying to find the right doll for me I chose Kimber. Not just for the awesome price and her beauty but her quality and construction as well. The fact that you are family owned tells me that you guys are going to take pride in the craftsmanship and customer care. Let’s face it, Kimber being the only doll you make also tells me you have all your focus on just her and perfecting your design. I bought her last night and cant wait for her to arrive. Thank you for being a company that is trusted and committed to quality in an industry so riddle with fake and inferior products who prey on first time buyers such as myself.